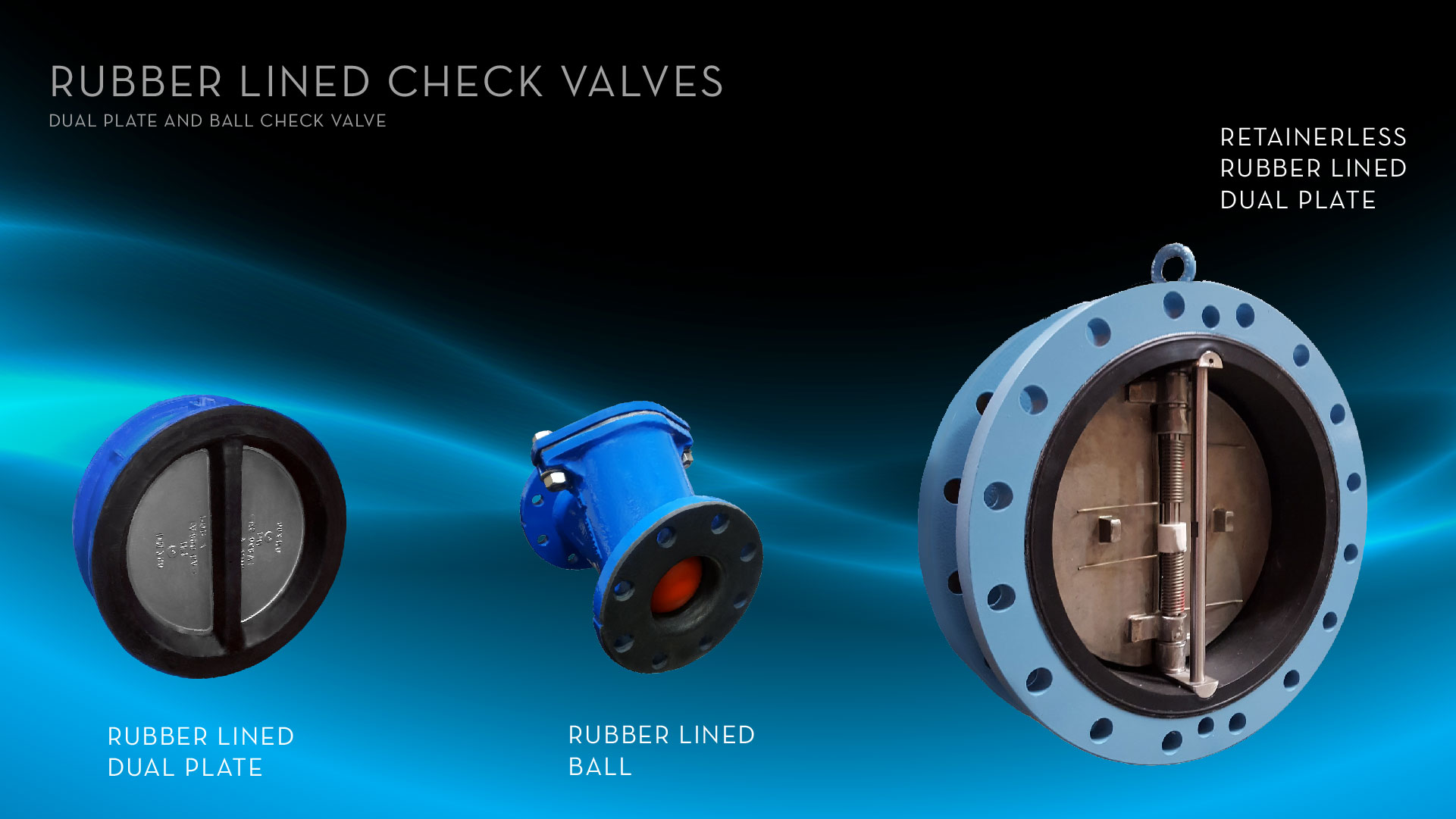

RUBBER LINED

DUAL PLATE AND BALL CHECK VALVE

WATER TECHNOLOGIES – IN HOUSE MANUFACTURING

DESIGN FEATURES

Ball check rubber lined with anti abrasive rubbers for mining industries application. The rubber lined dual plate check valves are a cheaper alternative to other alloyed materials which are resistant to corrosive applications. Available in several types of rubber.

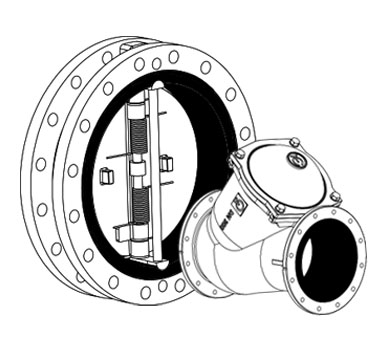

Castflow valves is producing the dual plate check valve with the same system that applies the butterfly valve with encircling liner. Meaning the body internally coated with rubber.

APPLICATIONS

Mining industries application

Seawater application

Purification systems

Mining

Chemical industries

TECHNICAL DATA

Ball check valves

RANGE: Flanged ends from DN 100 to DN 600

Dual Plate check valves

RANGE: DN 250 TO DN 1400

Retainerless Dual Plate check valves

RANGE: DN 350 TO DN 500

Design: Available ball check valves, dual plate and dual plate retairnerless

.

TECHNICAL PERFORMANCE

Good resistance to abrasion.Exceptional chemical resistance to many acids, base and solvents

SPECIAL ALLOYS

Over the years the most frequent used materials on the desalination market have been the so called “Superstainless” or “ superaustenitic”, which anti corrosive properties are superior to austenitic steels.

Due to the price increment on the prime materials and as an alternative more competitive for these materials, Duplex and Superduplex of second generation have been introduced in the market of desalination.

The family of Duplex and Super duplex Stainless steels offer a significant advantage over Standard austinic steels.

The 50/50 ferrite /austenite structure gives improved corrosion and abrasion resistance together with improved tensile and yield properties.

Duplex Composition range is obtained by a complex structure, and therefore requires a much greater degree of technology, melting and process control compared with austenitic stainless steel constructions.

CASTFLOW VALVES S.L. has been experiencing the production of check valves in Duplex stainless steel for the last years, increasing our knowledge on the complex casting technology.

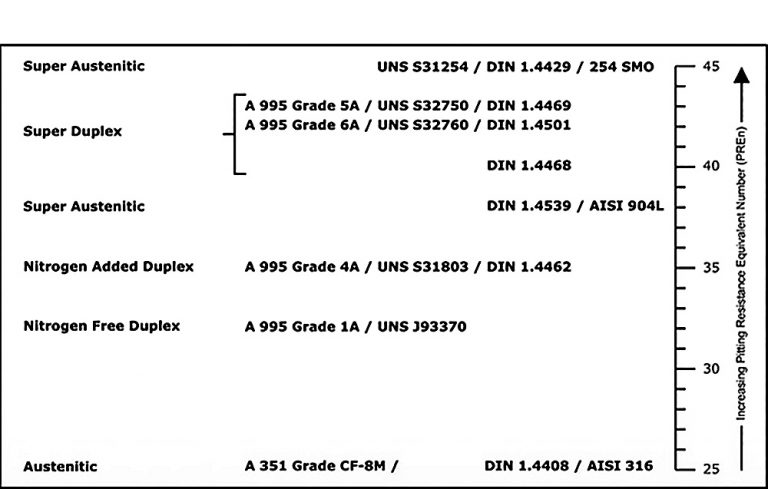

PITTING RESISTANCE EQUIVALENT NUMBER (PREN)

The resistance to pitting of an alloy is of vital importance , particularly so in handling seawater.

Assessment of resistance to pitting is often made by use of a pitting resistance equivalent number which, when this takes account of Cr Mo and N is referred to as a PREn Number.

Calculation is made on the basis of the following.

PREN= %Cr+ 3.3%Mo16%N