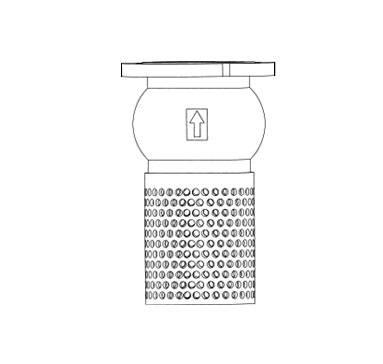

FOOT CHECK VALVES

WATER TECHNOLOGIES – IN HOUSE MANUFACTURING

DESIGN FEATURES

Are used to strain the liquids that flow into the aspiration, and therefore avoid entrée of too big elements that can damage the pipeline. Are mainly connected to the check valves for application as foot valve.

APPLICATIONS

Pumping stations

Water treatment and supply.

Networks for clean water distribution, irrigation (filtered water).

TECHNICAL DATA

Centred check disc valve

RANGE: DN 50 TO DN 900

Dual Plate check disc valve

RANGE: DN 50 TO DN 1400

Ball check disc valve

RANGE: FLANGED ENDS FROM DN 40 to DN 600

Design: Available from all our type of check valve in combination with strainers.

Strainers can be sold individual

Materials: galvanized steel,stainless AISI304 and AISI316.

.

MATERIALS

Standard: Galvanized steel with stainless steel bolting A2*.

Opcional: Stainless steel AISI304/AISI316 with stainless steel bolting A2*

SPECIAL ALLOYS

Over the years the most frequent used materials on the desalination market have been the so called “Superstainless” or “ superaustenitic”, which anti corrosive properties are superior to austenitic steels.

Due to the price increment on the prime materials and as an alternative more competitive for these materials, Duplex and Superduplex of second generation have been introduced in the market of desalination.

The family of Duplex and Super duplex Stainless steels offer a significant advantage over Standard austinic steels.

The 50/50 ferrite /austenite structure gives improved corrosion and abrasion resistance together with improved tensile and yield properties.

Duplex Composition range is obtained by a complex structure, and therefore requires a much greater degree of technology, melting and process control compared with austenitic stainless steel constructions.

CASTFLOW VALVES S.L. has been experiencing the production of check valves in Duplex stainless steel for the last years, increasing our knowledge on the complex casting technology.

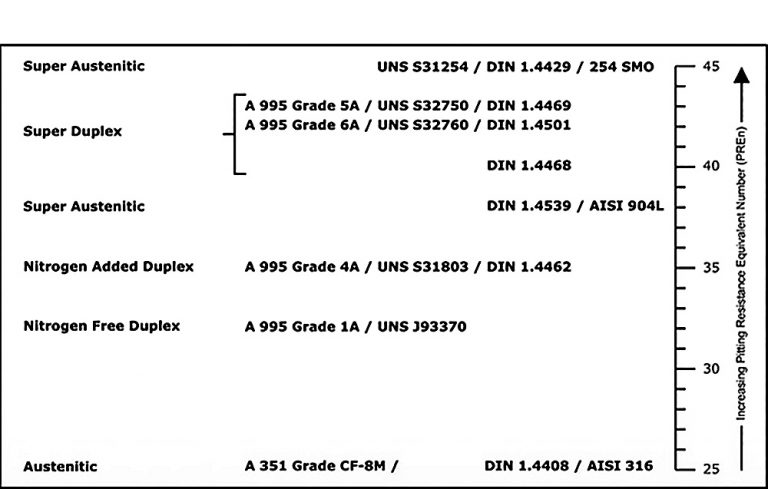

PITTING RESISTANCE EQUIVALENT NUMBER (PREN)

The resistance to pitting of an alloy is of vital importance , particularly so in handling seawater.

Assessment of resistance to pitting is often made by use of a pitting resistance equivalent number which, when this takes account of Cr Mo and N is referred to as a PREn Number.

Calculation is made on the basis of the following.

PREN= %Cr+ 3.3%Mo16%N